This Earth Day, many companies are focusing on climate goals and commitments. It seems that it is finally fashionable to be eco-conscious, with the Biden Administration aiming for carbon neutrality by 2050 and the country’s largest employers like Amazon Inc. committing to reach net-zero carbon by 2040. Others, feeling the urgency, are targeting a decidedly more ambitious date around 2030.

However, commitment can be seen as a form of harm reduction, or worse, green-washing versus making real change. We believe major and real impacts will come from nature-based solutions. Via photosynthesis processes, smart afforestation, and putting an end to deforestation, all while progressively moving towards the global decarbonization of our world.

How does your company or organization reach decarbonization goals and translate that into measurable impact? Although we cannot create an answer for you, we can share our approach and solution to the ever-pressing global climate concern, which is nature-based. That’s right, we’re pulling the CO2 the old-fashioned way - through photosynthesis.

Photo by Marta Matyszczyk on Unsplash

The Problem

With rising levels of CO2 resulting in climate change and increasingly destructive weather events, the question now being asked: How do we decarbonize, and reduce our collective carbon footprint?

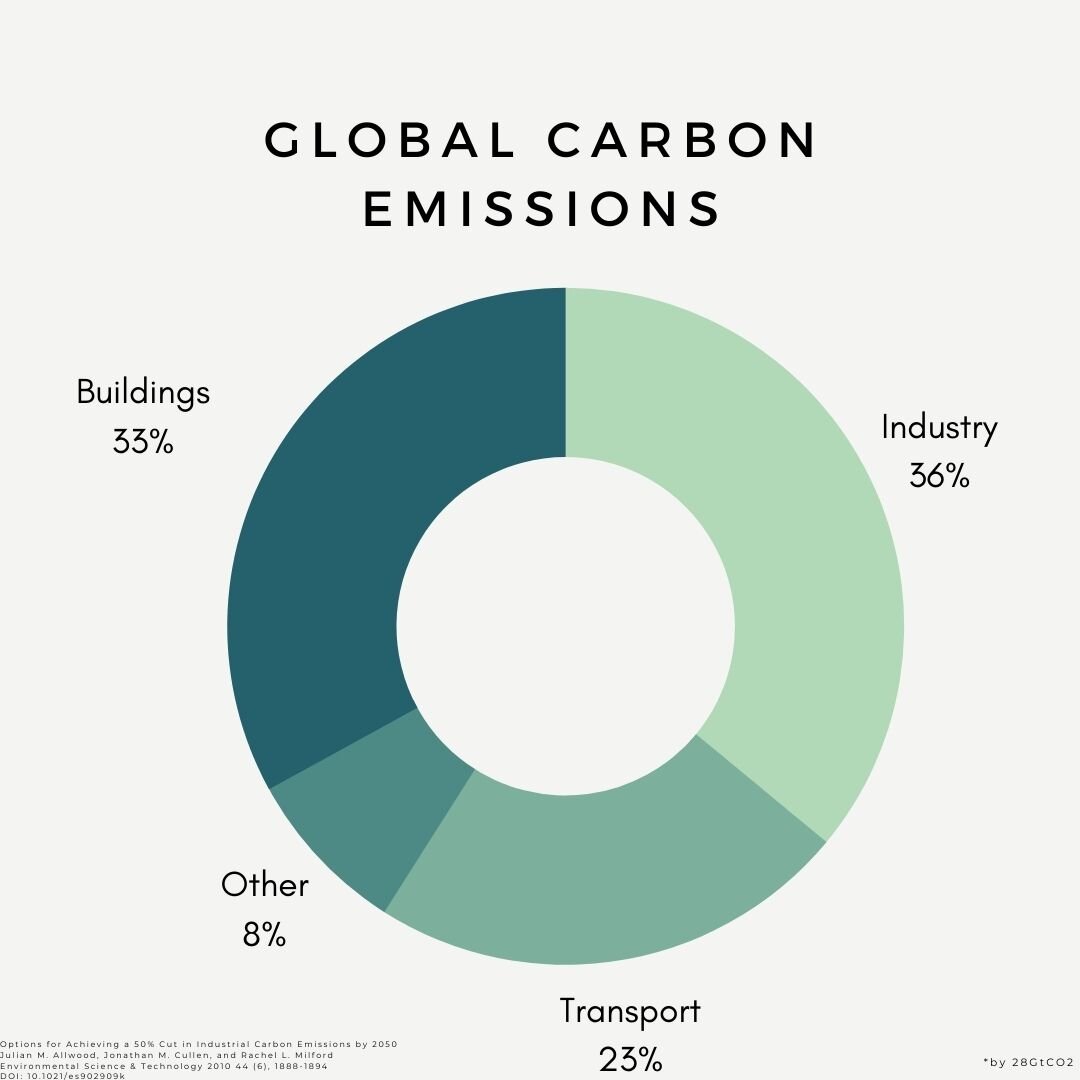

Data comparison of global carbon emissions

Data comparison of industrial carbon emissions

Over half of global carbon emissions come from manufacturing, building, and construction. With just the production of wood, conventional plastics, metals, and concrete accounting for 23% of global CO2 emissions (Nature Geoscience, 2021). A large chunk of this statistic comes specifically from concrete, at 8% (Chatham House, 2019), and steel contributing another 8% to the total global CO2 emissions (McKinsey, 2020).

Concrete and steel are both relatively dense compared to other materials, which in turn requires more energy to transport and utilize as a key construction/building input, not to mention higher temperatures to process. All of the mentioned materials can be categorized as super emitters, which means in aggregate they contribute significantly to the number of carbon emissions released into the atmosphere. This is where we are challenged to find alternatives.

Decarbonizing with Rapidly Renewable Plants

It's simple, composites, like Ekoa®, that are made from natural fibers and plant resins, reduce GHG emissions through photosynthesis.

The natural fibers utilized by Lingrove are categorized as rapidly renewable materials and consist of inputs that are able to regenerate themselves quickly (in 10 years or less). Growing our input materials, versus extracting them from the ground means we can theoretically use photosynthesis to create structures like houses/cars and make them carbon sinks. This can reduce the overall CO2 in our atmosphere, by further drawing it down into the ground.

Integrating carbon-negative materials to replace applications utilizing steel, concrete, plastics, and wood will substantially reduce GHG emissions across the entire manufacturing value chain.

Lingrove’s Solution

Lingrove’s formula to get to carbon negative is simple: carbon negative plants + renewable, energy-efficient manufacturing = lighter, stronger, and very low carbon products which can go into making better surfaces and structures.

Ekoa® in a home/furniture application

Ekoa® Surface product utilized as a wall covering

More about Ekoa®

Ekoa® is a natural fiber composite made with a higher stiffness-to-weight ratio than steel and lower density than carbon fiber (Pacific Testing Laboratories, 2015). Ekoa® uses extremely strong flax fibers as a substitute for high-emitting input materials and can be integrated into the production of commercial and residential interiors, automobiles, and consumer products. Natural composites, like Ekoa®, are poised to accelerate the shift towards lighter and stronger structures, from cars to modular homes, while helping reduce our carbon footprint

Sources:

Hertwich, E. G. (2021). Increased carbon footprint of materials production driven by rise in investments. Nature Geoscience, 14(3), 151–155. https://doi.org/10.1038/s41561-021-00690-8

Hoffmann, C., Hoey, M., & Zeumer, B. (2021, January 17). Decarbonization challenge for steel. McKinsey & Company. https://www.mckinsey.com/industries/metals-and-mining/our-insights/decarbonization-challenge-for-steel#:%7E:text=Every%20ton%20of%20steel%20produced,of%20global%20carbon%20dioxide%20emissions.

Making Concrete Change: Innovation in Low-carbon Cement and Concrete. (2020, December 14). Chatham House – International Affairs Think Tank. https://www.chathamhouse.org/2018/06/making-concrete-change-innovation-low-carbon-cement-and-concrete